In the world of **cutting-edge technology**, **Tesla** has long been known for its game-changing innovations, from electric vehicles to energy storage solutions. But there’s a shocking secret behind one of Tesla’s most ambitious projects—the **$100,000 stainless steel beast** that relies on an unlikely combination of **nuts and glue** to hold it all together. While the futuristic design and high price tag have earned attention, it’s the **unexpected use of basic materials** that has left many scratching their heads.

### **Tesla’s $100,000 Stainless Steel Beast: The Innovation That Sticks**

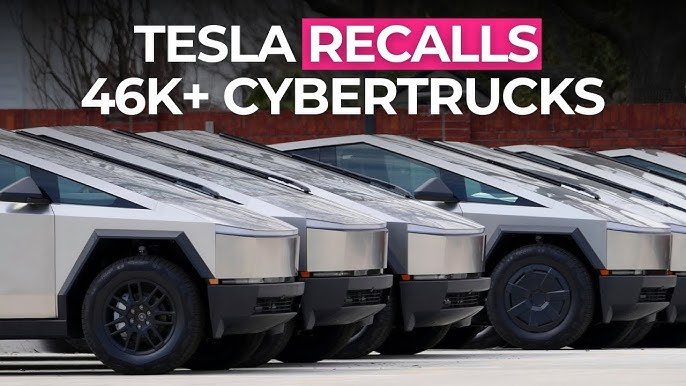

Tesla’s stainless steel marvel has been touted as a **revolutionary** step forward in both design and technology. But a recent revelation has shaken the industry to its core—**46,000 parts** of this engineering wonder are held together not by advanced welding techniques or futuristic adhesives, but by **nuts and glue**. This seemingly low-tech solution has raised eyebrows, leaving enthusiasts and critics alike questioning how something so basic could be part of such an expensive, cutting-edge product.

### **Why Use Nuts and Glue?**

At first glance, the use of **nuts and glue** might seem surprising, especially in a product that comes with a hefty **$100,000 price tag**. However, the decision to employ these materials is a testament to Tesla’s commitment to **cost efficiency** and **engineering ingenuity**. The **nuts** provide a **secure mechanical connection**, while the **glue** offers an extra layer of **flexibility and durability**, allowing the components to expand and contract without compromising the structural integrity of the vehicle.

This approach also **reduces weight** and **increases manufacturing speed**, making it an ideal solution for **Tesla’s fast-paced production lines**. Rather than relying on more complex and expensive methods, Tesla’s design engineers have embraced simplicity and **efficiency**, using these basic materials to bring their futuristic vision to life.

### **The Cutting-Edge Nature of Tesla’s Innovation**

What’s truly remarkable about this revelation is not just the use of nuts and glue, but how it underscores the spirit of **Tesla innovation**. By using everyday materials in an unexpected way, Tesla has showcased a deeper understanding of **engineering principles** and the **importance of material science**. The use of glue, for example, isn’t just a shortcut—it’s a **strategic choice** to improve the overall performance and reliability of the vehicle. It allows for more **flexibility in design**, particularly in high-stress areas of the frame, ensuring that the vehicle’s structure is both **lightweight and resilient**.

This blend of **simple materials and advanced design** proves that true innovation isn’t always about using the latest tech; sometimes, it’s about **finding clever solutions** that blend the old and the new. Tesla’s approach has opened up new possibilities for the future of manufacturing, where **efficiency** and **performance** can coexist without relying on overly complex or costly methods.

### **Tesla’s Stainless Steel Beast: What Does This Mean for the Future of Innovation?**

As surprising as it may seem, Tesla’s use of **nuts and glue** in their **$100,000 stainless steel beast** could pave the way for new **manufacturing techniques** that could revolutionize industries far beyond electric vehicles. By thinking outside the box and challenging traditional methods, Tesla is leading the way toward **smarter**, more **sustainable** production processes.

This unexpected twist in the **Tesla narrative** also raises a critical question: can other companies learn from Tesla’s example and apply these cost-saving measures in their own production lines? Could we see a future where **high-end products** are built not with high-tech materials but with more **affordable and sustainable solutions** that reduce waste and increase **production efficiency**?

### **Tesla’s Innovation with a Sticky Twist**

Tesla’s decision to use **nuts and glue** in its $100,000 stainless steel masterpiece is a reminder that innovation doesn’t always have to come from the latest gadgets or cutting-edge tech. Sometimes, the most innovative solutions come from **reimagining traditional materials** in ways that others might overlook. With **46,000 parts** held together by **nuts and glue**, Tesla’s **$100,000 stainless steel beast** is a true testament to the power of **creative engineering**, showing the world that innovation can come from the most **unexpected places**.